Project Description

This is one of my biggest projects in which I am attempting to create a dynamic and robust robot from the ground up.

The mechanics and PCB are designed in Fusion360, and the code written in C++ for microcontrollers while Python is used for simulation, gait generation and linear motor analysis.

Design

The design requirements:

- A robot with one leg which can jump (read: more than once)

- Untethered (battery powered)

With this in mind, there were a few options for design. I looked at a bunch of research papers with similar robots and settled on the inverted pendulum, voice coil actuator driven design.

One of the biggest challenges in this project is actuating the prismatic joint. My chosen actuator is a voice coil actuator (VCA), which suits the application perfectly because:

- It is compliant both when in operation and in standby mode

- The control of a uncommutated type VCA is super simple (a single H-Bridge)

- Relatively simple in construction

Looking at commercially available VCAs online, and reaching out to the 3-4 companies who produce them commercially, I realised that my only option was to create linear induction motor from scratch due to cost constraints.

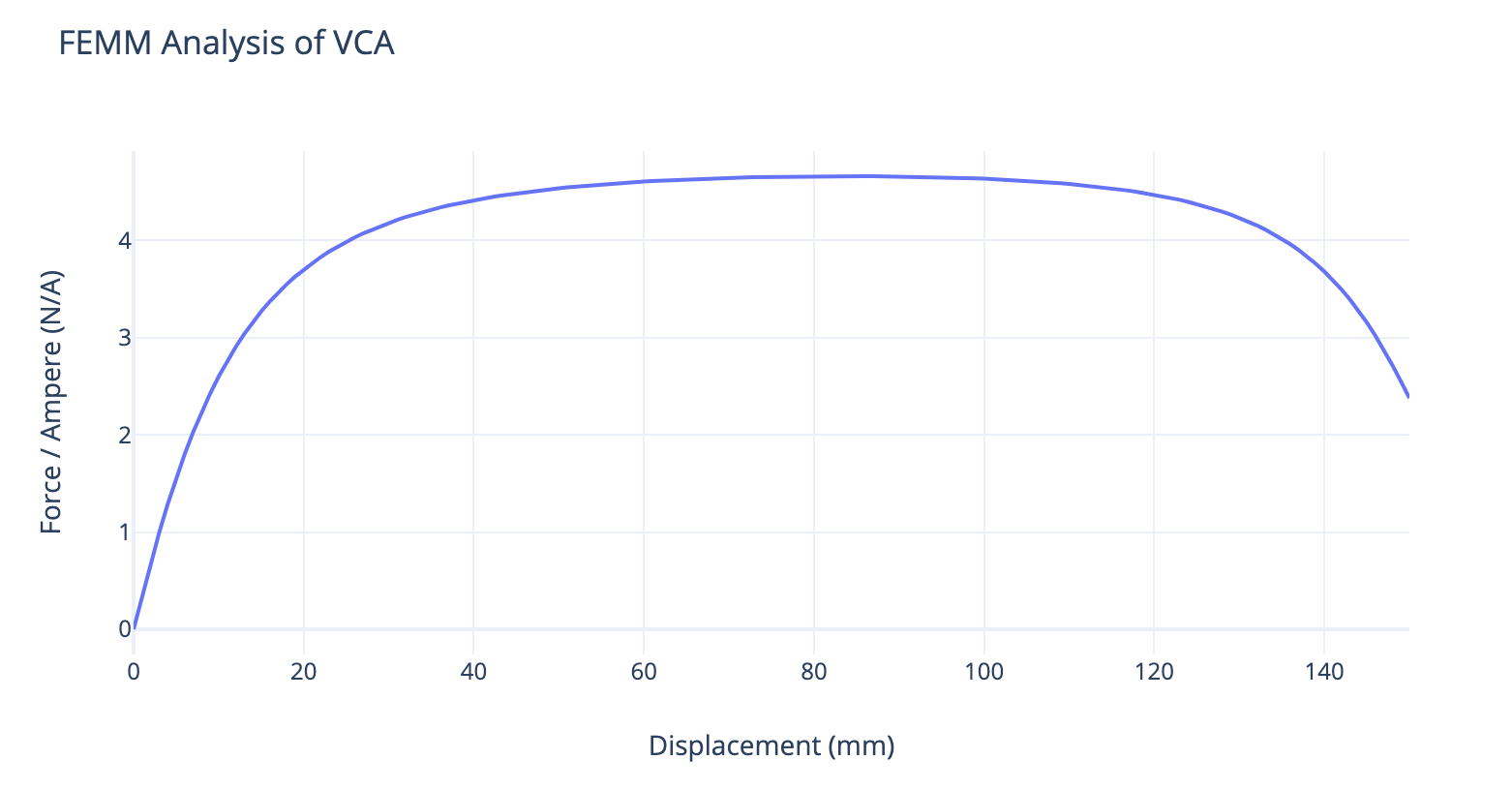

I started by creating a Jupyter notebook for the analysis of the VCA. This is crucial as coils are driven by a myriad parameters, such as coil dimensions, wire diameter, applied voltage, and much more.

I then ran my chosen coil design through an FEMM simulation to verify my analysis was correct.

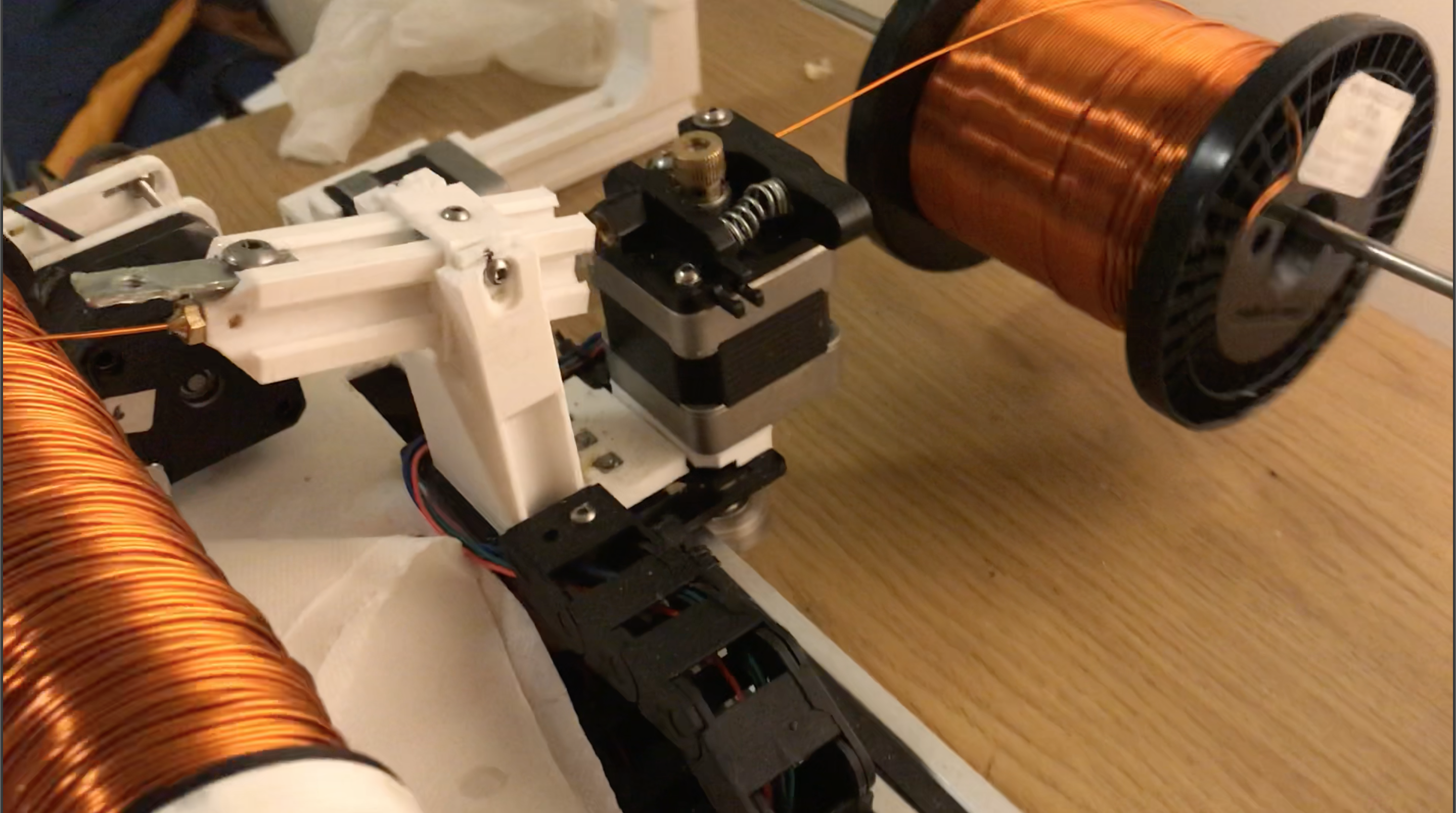

The next step was to manufacture the coil. To do this, I designed...

... and built ...

a coil winding robot!

Once I had the coil design done, I went on to design the jumping robot, Monopod.

The most involved aspect of this was creating the rotationally constrained spring-plunger that houses the magnets. Due to the VCA, I couldn't use ferrous materials in the vicinity.

This meant that traditional linear bearings and steel shafts were out. I researched other technologies and settled on Igus polymer bearings.

These are super cool, and can also be 3d printed with Igus' proprietary filament. In version 2 of the robot, I will use this fact to integrate the bearing into the coil, and remove the bearing housing at the bottom entierly.

For the feet, I am taking inspiration from Ben Katz from MIT Biomimetics and J Pipeper

and casting the feet with Smooth-On Flex Foam-IT 17 in a squash-ball-esque fashion.

For the knee joints, I originally wanted to use the MX-106T Dual Axis Robot Joint from Dynamixel, unfortunately the $1.2k price is out of the budget of this project. Alongside this, in order to reduce the inertia of the leg,

I decided to instead use a 2-axis gimbal mechanism which would be inside the body rather than below it. This has the advantage that the two axis of rotation are co-incindent, and that the center of mass lies on the intersection of the two axes.

For fabrication of the many custom parts, I created 3d printed jigs to ensure features such as tapped holes are precisely located. The jigs were used to fabricate the carbon fiber plunger, aluminium casing tube and the coil for the VCA.

The next step is to create a simulation of the robot with pyBullet, and from that be able to generate gaits for it! Thank you for viewing this project! :)

← Other Projects